iWAREHOUSE Success Stories

- share

-

Nova Scotia Liquor Corporation: Protecting All Assets

NSLC sought to protect it's biggest asset - it's people. NSLC encourages employees to take responsibility for themselves and their equipment, but managers needed better insight into the daily activities of the operators to be able to support this, along with more information that would allow them to make general warehouse decisions and improvements. They implemented iWAREHOUSE on their fleet of 40-plus forklifts to collect and report on operational and maintenance data for their fleet and operators.

-

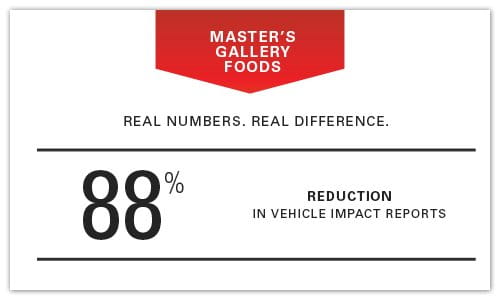

In-depth Fleet Data Helps Reduce Impacts and Manage Growth for Masters Gallery Foods

By utilizing the iWAREHOUSE forklift fleet management and warehouse optimization system, Masters Gallery Foods was able to address and decrease forklift impacts and damage in its facility.

-

Full Service Solutions Keep Darigold on Top

By utilizing the iTRACK fleet and asset management system, Darigold, Inc., achieved its goal of tracking all equipment maintenance costs in one place, streamlining the repair and upkeep process of its forklifts and standardizing its fleet to ensure the proper equipment was in use.

-

The Devil's in the Data for Bunzl North America

Vehicle utilization and service data from the iWAREHOUSE forklift fleet management system and iTRACK asset management system help Bunzl Distribution USA, Inc., to improve lift truck purchase planning and maintenance management.

-

For Romark Logistics, Fleet Optimization Becomes Critical Business Tool

Romark Logistics, a performance-driven 3PL, uses the iWAREHOUSE fleet management system to evaluate its service history, including costs and repair dates, to help analyze and drive down maintenance costs.

-

Warehouse Experiment Delivers Peak Performance for GENCO

GENCO integrated iWAREHOUSE with its Labor Management System for a cost savings that could be shared with both employees and customers and an employee incentive program that drove productivity to reduce pick labor, costs per unit and impacts.

You May Also Like:

Products

Browse the full suite of technology products available from iWAREHOUSE.

Learn More

About Us

Learn why iWAREHOUSE is the best solution to optimize your warehouse operations.

Learn More

iWAREHOUSE News

Read about the latest iWAREHOUSE news on our products and innovative telematics solutions.

Learn More

Resources

iWAREHOUSE downloads, literature, videos, white papers and customer testimonials.

Learn More